Fireclay Brick

Fire Clay Bricks | High Quality Refractory Bricks Manufacturer from China

Durable fire clay bricks with 30–48% Al₂O₃ content, ideal for furnaces, kilns, stoves, and chimneys. Wholesale supply directly from leading Chinese refractory brick manufacturer.

Fireclay bricks refer to clay products with Al2O3 content of 30%~48%. The fire resistance can reach 1690~1730 ℃. Refractory clay brick is made of clinker clay through mixing, molding, drying, sintering and proportioning. It has good corrosion resistance, wear resistance, thermal shock resistance, spelling resistance, high mechanical strength, and good volume stability under high temperature.

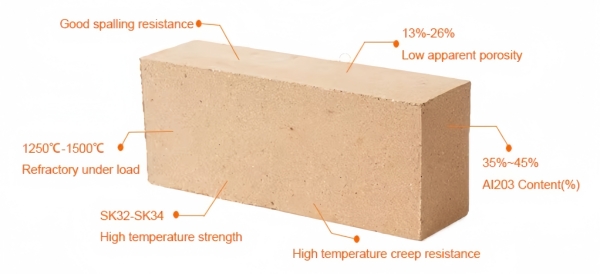

Characters of Fire Clay Brick:

•🔥High-Temperature Resistance:Refractoriness: 1,580–1,770°C,Stable at 1,300–1,450°C

•⚡Thermal Shock Resistant:Low expansion, survives rapid cooling/heating

•🛡️Acid Resistance:Fights CO/SO₂ & acidic slags

•🧱Stable Structure:Low shrinkage, no deformation

•💸Cost-Efficient:Affordable for industrial scaling

•🔧Easy to Install:Cut-to-fit, low maintenance

Typical Applications of Fire Clay Bricks:

•🔥Metallurgical Furnaces – lining for blast furnaces, hot blast stoves, ladles

•🧱Cement & Lime Kilns – transition zone, cooler sections

•🏡Home Heating Systems – fireplaces, wood stoves, pizza ovens

•♻️Environmental Equipment – waste incinerators, flue gas ducts

•🧪Petrochemical Plants – reformers, heaters, and combustors

Parameters of Fire Clay Bricks:

| Item | SK-30 | SK-32 | SK-34 | SK-35 |

|

Al₂O₃% (≥) |

30 | 35 | 38 | 45 |

|

Fe₂O₃% (≤) |

2.5 | 2.5 | 2 | 2 |

|

Refractoriness(SK) |

30 | 32 | 34 | 35 |

|

Refractoriness underload, 0.2MPa, °C (≥) |

1250 | 1300 | 1360 | 1420 |

|

Apparent porosity (%) |

20~26 | 20~24 | 20~22 | 18~20 |

|

Bulk density (g/cm³) |

1.9~2.0 | 1.95~2.1 | 2.1~2.2 | 2.15~2.22 |

|

Cold crushing strength ,MPa (≥) |

40 | 45 | 30 | 40 |

Q:Why Choose Our Fire Clay Bricks?

A;✅ Direct Manufacturer Price – Save costs with bulk supply from our factory

✅ Custom Design & OEM Branding – Tailored to your project or market

✅ Excellent Workability – Easy to cut, shape, and mortar

✅ Strong Thermal Stability – Withstands rapid heating and cooling

✅ Low Thermal Conductivity – Improves energy efficiency

Q:What is the maximum working temperature of fire clay bricks?

A:Standard fire clay bricks can withstand continuous temperatures up to 1400–1500°C, depending on the alumina content.

Q:What are the typical sizes and shapes available?

A:The most common size is 230×114×65 mm (9”x4.5”x2.5”), but custom shapes such as wedges, arches, and keys are available upon request.

Q:What are the main applications of fire clay bricks?

A:Fire clay bricks are used in blast furnaces, hot blast stoves, cement kilns, fireplaces, pizza ovens, incinerators, and other high-temperature environments.

Q:Are fire clay bricks suitable for outdoor use or home heating systems?

A:Yes, they are ideal for fireplaces, BBQ pits, wood stoves, and pizza ovens due to their heat insulation and thermal shock resistance.

Q:How do I choose the right fire clay brick for my application?

A:Selection depends on your operating temperature, furnace atmosphere, load-bearing requirements, and thermal shock conditions. Our technical team can help recommend the best option.

Q:Can fire clay bricks be used in waste incinerators or petrochemical plants?

A:Yes. Fire clay bricks are often used in low-to-medium temperature zones of incinerators, flue gas ducts, and heaters. For more extreme environments, consider upgrading to high alumina or phosphate-bonded bricks.

Q:What is the expected service life of fire clay bricks?

A:Depending on the application, proper installation, and operating conditions, fire clay bricks can last 2–5 years or longer.

Q:Do you offer OEM/ODM services or customized fire clay bricks?

A:Yes, we are a manufacturer and exporter with full support for custom sizes, shapes, OEM branding, and bulk order packaging.

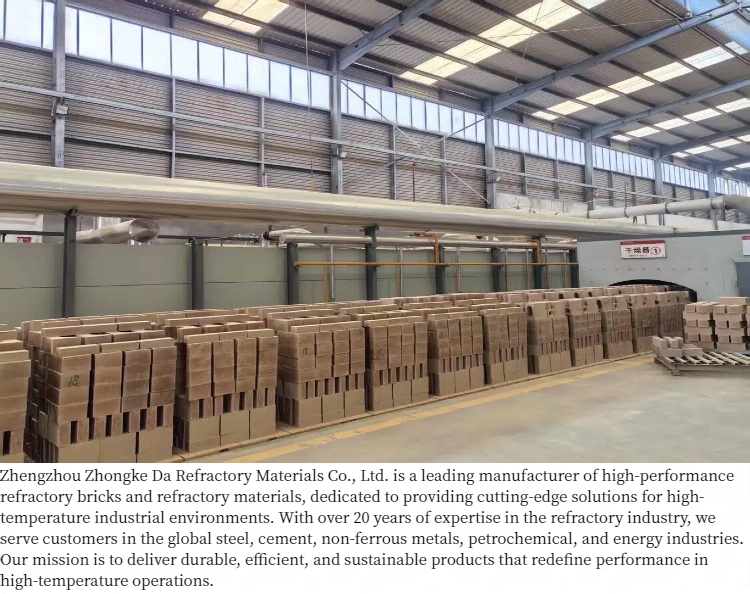

Zhengzhou Zhongkeda Refractory Materials Co., Ltd

Zhengzhou Zhongkeda Refractory Materials Co., Ltd