Corundum Brick

Corundum Brick | High-Purity Alumina Refractory Bricks Manufacturer China

Premium-Grade Corundum Bricks for Extreme High-Temperature Industrial Applications

Corundum Brick is a refractory product made from high-purity alumina (Al₂O₃ ≥90%) as the main raw material, produced through high-temperature sintering or electrofusion. Its primary mineral phase is corundum (α-Al₂O₃), which features exceptionally high hardness and chemical stability.

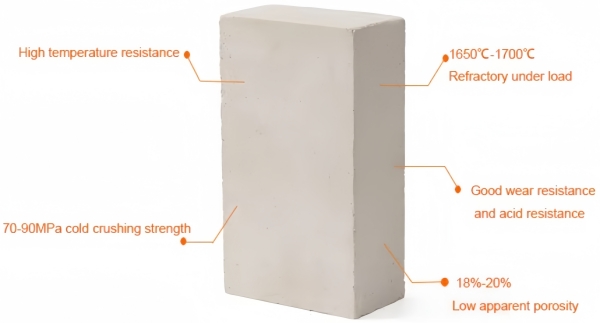

Characters of Corundum Brick:

•🔥Ultra-High Refractoriness: Stable at extreme temperatures up to 1800°C

•🛡️Corrosion & Erosion Resistant: Excellent protection against slag, molten metal, alkali & acids

•💪High Strength & Density: Ensures long service life in harsh working environments

•♻️Outstanding Thermal Shock Resistance: Suitable for frequent heating and cooling cycles

•🧱Precision Shaped & Customizable: Tailored to your furnace lining designs

Classification of Corundum Bricks:

•Sintered Corundum Brick:Sintered corundum brick is a refractory product made from sintered alumina clinker. This type of brick has a high melting point and remains stable at high temperatures. It exhibits excellent mechanical strength and wear resistance at both room and elevated temperatures. Additionally, it offers superior resistance to metal corrosion and oxidation-reduction reactions.

•Fused Corundum Brick:Fused corundum brick is primarily composed of α-Al₂O₃ and β-Al₂O₃ as its main crystalline phases. It features a dense crystal structure, providing excellent resistance to molten glass corrosion. Moreover, it demonstrates good wear resistance at high temperatures and does not contaminate molten glass, making it an ideal choice for glass industry applications.

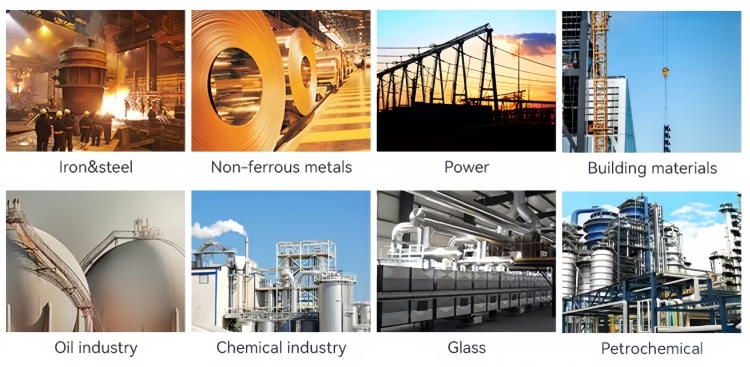

•🔥Steel Industry: Ladle lining, tundish working lining, EAF roofs

•🔍Glass Furnaces: Regenerator checkers, side walls

•🛠️Non-Ferrous Metals: Aluminum reduction cells, zinc smelters

•⛽Petrochemical: Gasifier linings, reformers

•♻️Waste Incinerators: Hot zones, wear-resistant linings

Parameters of Corundum Bricks:

| Item |

Ultra Purity Corundum Brick |

99 Corundum Brick |

90 Corundum Brick |

Corundum-Mullite Brick |

| Al₂O₃(%)≥ | 99.3 | 98.5 | 90 | 80 |

|

SiO₂(%)≤ |

0.15 | 0.3 | 8.5 | 18.5 |

|

Fe₂O₃(%)≤ |

0.1 | 0.2 | 0.2 | 0.3 |

|

Bulk density(g/cm³)≥ |

3.25 | 3.25 | 3.1 | 2.9 |

|

Apparent porosity(%)≤ |

18 | 18 | 18 | 18 |

|

Cold crushing strength(MPa)≥ |

100 | 100 | 120 | 120 |

|

Refractoriness under load, ℃(0.2MPa,0.6%)≥ |

1700 | 1700 | 1700 | 1700 |

|

Reheating linear change rate, %(1600℃ x 8h) |

-0.2 | -0.2 | 0.2 | 0.2 |

|

Thermal expansion coefficient, x 10-6 (Room temp. to 1300’C) |

8.1 | 8.1 | 8.1 | 7.6 |

Q: What is the maximum working temperature of your corundum bricks?

A: Our bricks can withstand continuous temperatures up to 1800°C (3272°F), depending on the Al₂O₃ content and density.

Q;What shapes and sizes are available?

A:We provide:

•Standard bricks: straight, wedge, arch shapes

•Customized designs: based on your drawings or furnace lining needs

Need OEM shapes or CAD support? Contact us.

Q:Are your corundum bricks suitable for steel ladle slag lines?

A:Yes, our dense corundum bricks are ideal for slag line areas, with superior slag penetration resistance and thermal shock performance, achieving up to 80–150 heats lifespan.

Q:Do you offer corundum bricks with zirconia or spinel additives?

A:Yes, we can produce ZrO₂-enhanced corundum bricks or alumina-spinel bricks on request to meet specific slag resistance or thermal expansion control requirements.

Q:How do you package the corundum bricks for export?

A:•Export-standard fumigated wooden pallets

•Plastic wrap + corner protectors to prevent breakage

•Customized labels and shipping marks available

Q:What is your lead time and MOQ?

A:•Standard shapes: 7–15 days

•Customized orders: Negotiable

•MOQ: Typically 10 tons, but trial orders are welcome

Zhengzhou Zhongkeda Refractory Materials Co., Ltd

Zhengzhou Zhongkeda Refractory Materials Co., Ltd