Bauxite

High Purity Calcined Bauxite for Refractory Use

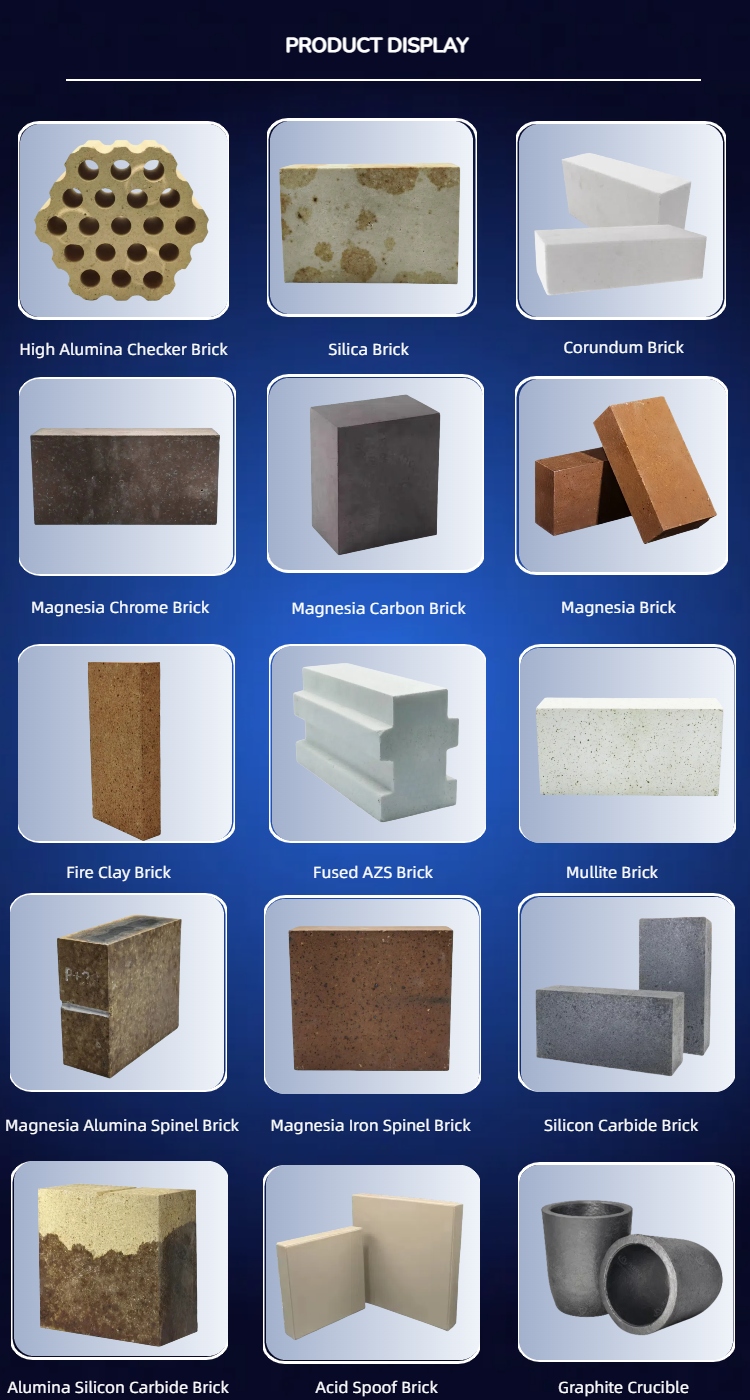

Refractory-grade bauxite for bricks, castables, and high-temperature industrial applications.

Bauxite (aluminous soil; bauxite) is also called bauxite or bauxite. Its main component is alumina, which is hydrated alumina containing impurities. It is an earthy mineral. White or off-white, brown or light red due to iron content. Density 3.45g/cm3, hardness 1~3, opaque and brittle. Extremely difficult to melt. Insoluble in water, soluble in sulfuric acid and sodium hydroxide solutions. Mainly used for smelting aluminum and making refractory materials.

Calcined bauxite is a raw material with high alumina content and excellent thermal performance, widely used in the refractory, foundry, and metallurgy industries. It is made by sintering bauxite ore at high temperatures to improve hardness and remove moisture.

Characters of Calcined Bauxite:

•High Alumina Content:Contains 85%–90% Al₂O₃ for superior heat resistance and structural integrity.

•Excellent Thermal Stability:Maintains performance under extreme high-temperature environments, up to 1700°C.

•Low Impurity Levels:Strictly controlled Fe₂O₃ and TiO₂ content ensures minimal contamination and higher efficiency.

•Customizable Grain Sizes:Available in 0-1mm, 1-3mm, 3-5mm, 0-5mm, powder – or customized per application.

•Ideal for Refractory & Foundry Use:Widely used in refractory bricks, castables, ladle linings, metallurgy, and precision casting.

Application of Calcined Bauxite:

•Refractory bricks for kilns and furnaces | •Castables and low cement castables | •Metallurgy and slag conditioners

•Anti-skid road aggregates | •Abrasives

Parameters of Calcined Bauxite:

|

Item |

A-45 |

A-60 |

A-70 |

A-75 |

A-80 |

A-90 |

|

|

Dry Density (g/cm3) ≥ |

2.3 | 2.5 | 2.6 | 2.65 | 2.7 | 3 | |

|

Chemical (%) |

Al₂O₃≥ |

45 | 60 | 70 | 75 | 80 | 90 |

|

ZrO₂ |

- |

- |

- |

- |

- |

- |

|

|

Modulus of Rupture (Mpa) |

110℃×24h≥ |

5 | 8 | 9 | 9 | 10 | 12 |

|

1500℃×3h≥ |

8 | 10 | 10 | 10 | 12 | 15 | |

|

Compressive Strength (Mpa) |

110℃×24h≥ |

30 | 40 | 40 | 45 | 45 | 60 |

|

1450℃×3h≥ |

60 | 80 | 80 | 85 | 90 | 85 | |

|

Linear Dimensional Change After Fired (1500℃×3h)%≤ |

±0.5 |

||||||

|

Refractoriness(℃)≥ |

1710 |

1740 | 1790 |

1790 |

1790 |

1790 |

|

|

Working Temp(℃) |

1450 |

1450 |

1500 | 1550 | 1600 | 1650 | |

FAQ:

Q:What is refractory grade bauxite?

A:Refractory grade bauxite is a specially selected raw bauxite ore that is calcined at high temperatures to enhance its alumina content and thermal resistance. It is ideal for refractory bricks, castables, and furnace linings.

Q:What is the typical Al₂O₃ content in calcined bauxite for refractory use?

A:Our refractory calcined bauxite contains 85% to 90% Al₂O₃, with low iron and low silica levels, making it suitable for high-performance refractory applications.

A:We provide bauxite in a variety of sizes: 0–1mm, 1–3mm, 3–5mm, 0–5mm, and powder, tailored to refractory production needs. Custom sizes are available on request.

Q:Is your calcined bauxite suitable for making refractory bricks?

A:Yes, our high-purity calcined bauxite is widely used in high-alumina refractory bricks, fireclay bricks, insulating bricks, and other heat-resistant materials.

Q:Do you offer free samples of refractory-grade bauxite?

A:Yes, we provide free samples (1–2kg) of our calcined bauxite for quality checking. Buyers only need to pay for courier shipping.

Q:What packaging options do you offer for bauxite?

A:Bauxite is packed in 25kg bags, 1MT jumbo bags, or per customer request. We also support palletization and OEM custom packaging for overseas buyers.

Zhengzhou Zhongkeda Refractory Materials Co., Ltd

Zhengzhou Zhongkeda Refractory Materials Co., Ltd