Magnesia Brick

Magnesia Refractory Bricks for High-Temperature Industrial Applications

High-Purity Magnesia Bricks | Direct-Bonded Magnesia Bricks | China Magnesia Brick Manufacturer

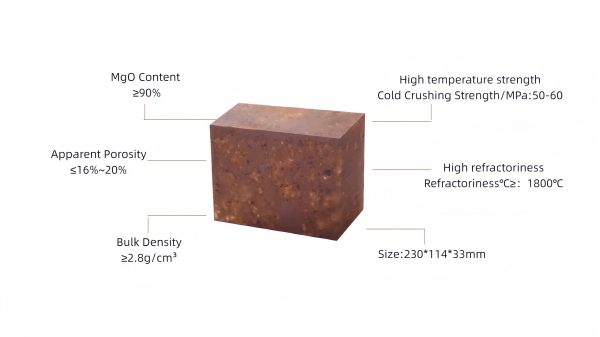

The main component of magnesia bricks is magnesium oxide (MgO), with a typical MgO content of over 90%. The primary crystalline phase is periclase. Magnesia bricks are generally classified into sintered magnesia bricks and fused magnesia bricks. In sintered magnesia bricks, those with direct bonding are called directly bonded magnesia bricks, while those produced through electrofusion are referred to as rebonded magnesia bricks.

Characters of Magnesia Refractory Brick:

•🔥High Refractoriness: Withstands temperatures above 2000℃, suitable for high-temperature environments.

•🛡️Alkali Slag Resistance: Excellent resistance to alkaline slag, making it ideal for alkaline environments.

•🔄Thermal Shock Resistance: Can endure rapid temperature fluctuations without cracking.

•💪High Mechanical Strength: Maintains strong mechanical properties even at high temperatures.

•🧪Corrosion Resistance: Strong resistance to alkaline substances and molten metal slag.

Typical Applications of Magnesia Refractory Bricks:

•🏭Steel Industry: Converter linings, electric arc furnace (EAF) linings, ladle slag zones

•🏗️Cement Industry: Transition zone and burning zone of rotary kilns

•🔶Non-Ferrous Metallurgy: Smelting furnaces for copper, nickel, and lead

•🥃Glass Industry: Regenerative chambers and checker bricks

Paramaters of Magnesia Refractory Brick:

Item

M-98

M-97A

M-97B

M-95A

M-95B

M-91

M-89

MgO(%)≥

97.5

97

96.5

95

94.5

91

89

SiO₂(%)≤

1.0

1.2

1.5

2.0

2.0

3.0

3.0

CaO(%)≤

/

/

/

2.0

2.0

3.0

3.0

Apparent Porosity(%)≤

16

16

18

16

18

18

20

Bulk Density(g/cm³)≥

3

3

3

2.95

2.95

2.90

2.85

Cold Crushing Strength(MPa)≥

60

60

60

60

60

60

50

0.2MPa Refractoriness Under Load(℃)≥

1700

1700

1700

1650

1650

1560

1500

Permanent Linear Change After Heating(%)

Shape & Size of Magnesia Refractory Brick:

FAQ:

Straight

Split

Arch

Wedge

Tile

Other Shape

L×W×H(mm)

L×W×H (mm)

L×W×H/h(mm)

L×W×H/h (mm)

L×W×H (mm)

Key brick

230×114×65

230×114×25

230×114×65/45

230×114×65/45

230×230×38

Skew brick

230×114×75

230×114×32

230×114×65/55

230×114×65/55

230×230×50

Soap

230×114×37

230×114×75/45

220×114×75/45

230×230×65

Checker

230×114×50

230×114×75/55

220×114×75/55

230×230×75

Neck

230×114×75/65

220×114×75/65

Taper

Q:What is the maximum service temperature of magnesia refractory bricks?

A:Magnesia bricks can withstand temperatures up to 1900°C, depending on the grade and application. Fused magnesia and direct-bonded magnesia bricks offer even better performance in extreme environments.

Q: Are magnesia bricks resistant to slag and corrosion?

A:Yes. Due to their alkaline nature, magnesia bricks offer excellent resistance to basic slags, particularly in steelmaking furnaces and ladle linings.

Q:What are the differences between sintered and fused magnesia bricks?

A:•Sintered magnesia bricks are made from calcined magnesite and offer good refractoriness.

•Fused magnesia bricks are made using electrofused magnesia, providing higher density, slag resistance, and thermal shock stability.

Q:Do you offer custom sizes or shapes for magnesia bricks?

A:Yes. We support customization of sizes and shapes based on customer furnace design and specifications. Drawings or samples are welcome for OEM production.

Q:Do magnesia bricks have good thermal shock resistance?

A:Yes, especially fused magnesia bricks and magnesia-chrome bricks. Thermal shock resistance is critical in frequent cycling environments, such as EAF and ladle operations.

Q:What is the packaging method for export?

A:Bricks are packed on fumigated wooden pallets, wrapped with waterproof plastic film, and secured with steel bands to prevent damage during sea transport.

Q: What grades of magnesia bricks do you supply?

A:We offer:

•Ordinary sintered magnesia bricks (90–92% MgO)

•High-purity magnesia bricks (≥95% MgO)

•Fused magnesia bricks

•Magnesia-carbon bricks

•Magnesia-chrome bricks

Each grade targets different industrial needs and budgets.

Q: Which countries do you export magnesia bricks to?

A:We’ve exported to over 30 countries, including the USA, Germany, India, Turkey, Brazil, South Africa, Vietnam, and Indonesia, serving global steel plants, cement kilns, and glass factories.]

Zhengzhou Zhongkeda Refractory Materials Co., Ltd

Zhengzhou Zhongkeda Refractory Materials Co., Ltd