Fused AZS Brick

Fused AZS Brick | High-Performance Refractory Bricks for Glass Furnaces

Fused AZS bricks (Alumina-Zirconia-Silica) are premium refractory materials widely used in glass melting furnaces. With excellent resistance to glass corrosion, low contamination, and high thermal stability, they are ideal for critical areas such as the glass contact zone, throat, or sidewalls.

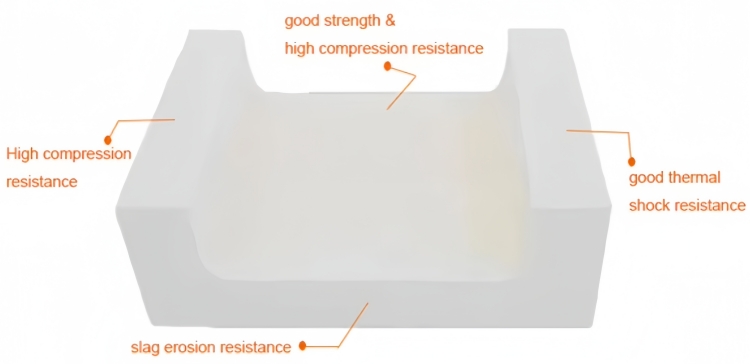

Characters of Fused AZS Brick:

•🛡️Excellent resistance to molten glass corrosion

•🔥High refractoriness and thermal shock resistance

•💎Low bubble index, minimal glass contamination

•🔧Smooth surface, precise dimensions, easy to install

•🧪Stable chemical structure and long service life

|

Types |

ZrO₂ Content |

Core Features |

Typical Applications |

|

AZS-33 |

33% |

Lower cost, moderate corrosion resistance |

Upper structure of glass melting furnaces, regenerator chambers |

|

AZS-36 |

36% |

Balanced corrosion resistance and thermal shock stability |

Sidewalls of the melting zone in glass furnaces, throat areas |

|

AZS-41 |

41% |

Superior corrosion resistance, highest cost |

Tin bath of float glass production, photovoltaic glass furnaces |

|

Item |

AZS-33 | AZS-36 | AZS-41 |

|

SiO₂ (%)≤ |

16 | 14 | 13 |

|

Al₂O₃ (%) |

The Remainder |

The Remainder |

The Remainder |

|

ZrO₂ (%) |

32~36 | 35~40 | 40~44 |

|

Fe₂O₃+TiO₂+CaO+MgO+Na₂O+K₂O (%)≤ |

2 | 2 | 2 |

|

Bulk Density (g/cm³)≥ |

3.75 | 3.8 | 3.95 |

|

Apparent Porosity (%)≤ |

1.5 | 1.0 | 1.0 |

|

Initial Precipitation Temperature of Vitreous Phase (℃)≥ |

1400 | 1400 | 1400 |

|

Vitreous Phase Exudation (%) |

2 | 3 | 3 |

|

Anti-molten Glass Erosion Speed Under Static Condition, mm/24h (1500℃*36h, ordinary soda lime glass)≤ |

1.6 | 1.5 | 1.3 |

|

Bubble Release Rate, % (1300℃*10h, ordinary soda lime glass)≤ |

2.0 | 1.5 | 1.0 |

Q: What are the differences between AZS-33, AZS-36, and AZS-41 grades?

A:•AZS-33: Standard corrosion resistance, economical, used for superstructures.

•AZS-36: Better corrosion resistance and service life, ideal for sidewalls and throats.

•AZS-41: Highest corrosion resistance and purity, used in glass contact and critical areas.

Q: How do fused AZS bricks minimize glass contamination?

A: Thanks to their low apparent porosity and dense structure, fused AZS bricks prevent bubbles and exudation of the glass phase, ensuring a cleaner glass product.

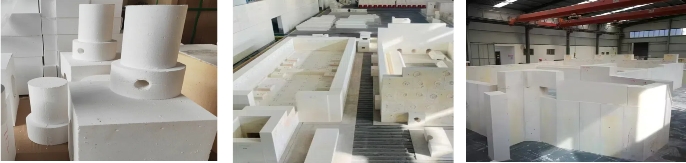

Q: Can you manufacture customized shapes and dimensions?

A: Yes, we can customize fused AZS bricks according to your drawings or specific furnace designs.

Q: Do you provide quality certifications?

A: Yes, each batch comes with a quality certificate. Third-party inspection reports can also be arranged if required.

Q: What is your MOQ (Minimum Order Quantity)?

A: Our standard MOQ is 10 tons, but for trial orders or special projects, we are flexible and open to negotiation.

Q: How are fused AZS bricks packaged?

A: Bricks are packed in sturdy wooden crates with plastic film and foam padding inside to protect against moisture and mechanical damage during transportation.

Q: What are the available shipping methods?

A: We can arrange sea freight, air freight, or land transportation depending on your location and project schedule. FOB, CIF, and DDU terms are available.

Q: How long is the production lead time?

A: Generally 30–45 days after receiving the deposit, depending on the order quantity and customization requirements.

Q: How should the bricks be stored before installation?

A: Store in a dry, ventilated place. Avoid moisture and mechanical impact. Once unpacked, the bricks should be installed as soon as possible to maintain optimal performance.

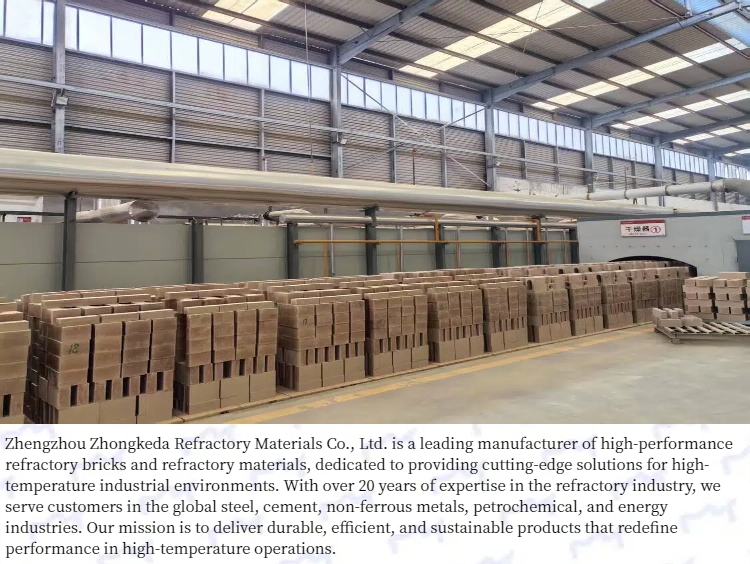

Zhengzhou Zhongkeda Refractory Materials Co., Ltd

Zhengzhou Zhongkeda Refractory Materials Co., Ltd