Silica Brick

Silica Bricks for High-Temperature Applications

Premium Refractory Solution for Coke Ovens, Glass Furnaces, and Hot Blast Stoves

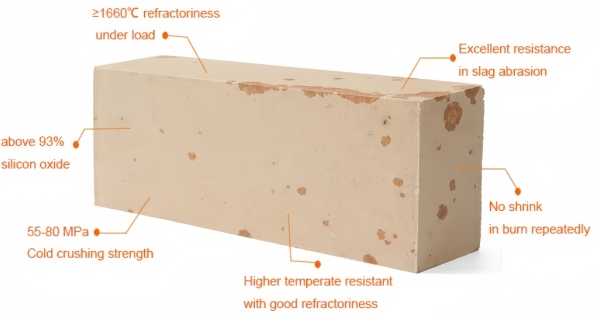

Silica brick is an acidic refractory material primarily composed of silicon dioxide (SiO₂) with a content of ≥93%. It is manufactured through a high-temperature firing process. Its mineral composition mainly consists of cristobalite and tridymite. Silica brick has a high refractory temperature and strong resistance to acidic slag erosion but has weak resistance to alkaline slag.

Characters of Silica Bricks:

•🔥High Refractoriness:Silica bricks have a refractoriness of up to 1710-1730℃, making them suitable for high-temperature environments such as steelmaking furnaces and glass melting kilns.

•🌡️High-Temperature Volume Stability:At high temperatures, silicon dioxide transforms into cristobalite and tridymite, resulting in minimal volume change. This ensures long-term stability and resistance to deformation under prolonged high-temperature use.

•🛡️Resistance to Acidic Slag Erosion:Silica bricks exhibit strong resistance to acidic slags (such as those with high SiO₂ content) but have poor corrosion resistance to alkaline slags (CaO, MgO, etc.).

•⚠️Low-Temperature Brittleness:Below 600℃, phase transformation (quartz → tridymite) may cause volume expansion, requiring careful temperature control during heating.

Typical Applications of Silica Bricks:

•🏭Coking Furnace: Furnace walls and furnace roofs in the carbonization chamber and combustion chamber.

•🧿Glass Melting Furnace: High-temperature areas such as the furnace roof and breast wall.

•🏗️Hot Blast Stove: High-temperature sections such as checker bricks and arch roofs.

•🧱Ceramic Kiln: High-temperature firing zone structures.

•♻️Electric Steel Furnace: Furnace roof and some parts of the furnace walls.

| Item | GZ-93 | GZ-94 | GZ-95 | GZ-96 |

|

SiO₂(%)≥ |

93 | 94 | 95 | 96 |

|

Fe₂O₃(%)≤ |

1.6 | 1.4 | 1.2 | 1.0 |

|

Refractoriness(℃)≥ |

1690 | 1710 | 1710 | 1710 |

|

Apparent Porosity(%)≤ |

25 | 23 | 22 | 22 |

|

Cold Crushing Strength (MPa)≥ |

19.6 | 24.5 | 29.4 | 29.4 |

|

0.2MPa Refractoriness Under Load(℃)≥ |

1620 | 1640 | 1650 | 1660 |

|

True density(g/cm³)≤ |

2.39 | 2.39 | 2.39 | 2.39 |

| Item |

Furnace Bottom |

Furnace Wall |

Other |

|

SiO₂(%)≥ |

94.5 | 94.5 | 94 |

|

Apparent Porosity(%)≤ |

22 | 22 | 24 |

|

Cold Crushing Strength (MPa)≥ |

40 | 35 | 28 |

|

0.2MPa Refractoriness Under Load(℃)≥ |

1650 | 1650 | 1650 |

|

Permanent Linear Change After Heating(1450℃*2h)/% |

0~0.2 |

0~0.2 |

0~0.2 |

|

True density(g/cm³)≤ |

2.33 | 2.33 | 2.34 |

|

Thermal Expansion(1000℃)/%≤ |

1.28 | 1.28 | 1.30 |

3.Silicon bricks for hot blast stove

|

Item |

Dome Wall Brick |

Checker Brick |

|

SiO₂(%)≥ |

95 | 95 |

|

Apparent Porosity(%)≤ |

22(24) | 24 |

|

Cold Crushing Strength (MPa)≥ |

40(30) | 30 |

|

0.2MPa Refractoriness Under Load(℃)≥ |

1650 | 1650 |

|

True density(g/cm³)≤ |

2.33 | 2.34 |

|

Thermal Expansion(1000℃)/%≤ |

1.26 | 1.26 |

|

0.2MPa/1550℃ Creep Rate(0 h⁓50 h)≤ |

0.8 | 0.8 |

FAQ:

Q:What is the maximum service temperature of silica bricks?

A:Silica bricks can withstand continuous working temperatures of up to 1650–1700°C, making them ideal for high-temperature furnaces such as coke ovens and glass melting chambers.

Q:What is the typical SiO₂ content in your silica bricks?

A:Our standard silica bricks contain ≥94% SiO₂, ensuring excellent thermal stability and corrosion resistance in acidic environments.

Q:Are silica bricks suitable for glass furnace crown lining?

A:Yes, due to their high refractoriness, low thermal expansion, and excellent acid resistance, silica bricks are widely used in the crown of glass furnaces.

Q:Can I get customized sizes or special shapes?

A:Absolutely. We offer OEM/ODM customization, including skew bricks, checker bricks, arch bricks, and more. Just send us your drawings or specifications.

Q:How are silica bricks packaged for export?

A:Silica bricks are packed in fumigated wooden pallets or boxes, with plastic film wrapping for moisture protection, ensuring safe international shipping.

Q:What industries use silica bricks?

A:Silica bricks are widely used in:

•Coke ovens (walls and roofs)

•Glass furnaces (crown and breast walls)

•Hot blast stoves (checker chambers)

•Acidic industrial furnaces

Q:Are your silica bricks compliant with international standards?

A:Yes, our silica bricks are manufactured according to ISO 9001 and ASTM C155 standards, with consistent quality control and third-party testing available upon request.

Q:Do you offer technical support or installation guidance?

A:Yes, we provide technical consultation, refractory design assistance, and installation guidance to ensure optimal performance for your project.

Zhengzhou Zhongkeda Refractory Materials Co., Ltd

Zhengzhou Zhongkeda Refractory Materials Co., Ltd