Sillimanite Brick

Sillimanite Brick – High-Performance Refractory Solutions for High-Temperature Kilns

Sillimanite Bricks are high-alumina refractory products made from natural sillimanite minerals. When fired at high temperatures, sillimanite transforms into mullite and free silica, providing excellent thermal shock resistance, high refractoriness, and structural integrity under load. These properties make it ideal for use in glass furnaces, ceramic kilns, cement rotary kilns, and steel industry reheating furnaces.

Characters of Sillimanite Bricks:

•🔥Refractoriness: >1770°C

•🧱High Load-Bearing Capacity: Excellent resistance under high-temperature mechanical stress

•♻️Good Thermal Shock Resistance: Minimizes cracking under temperature fluctuations

•🧪Corrosion Resistance: Withstands attack from slags and high-temperature gases

•💡Stable Volume Performance: Minimal shrinkage at high temperatures

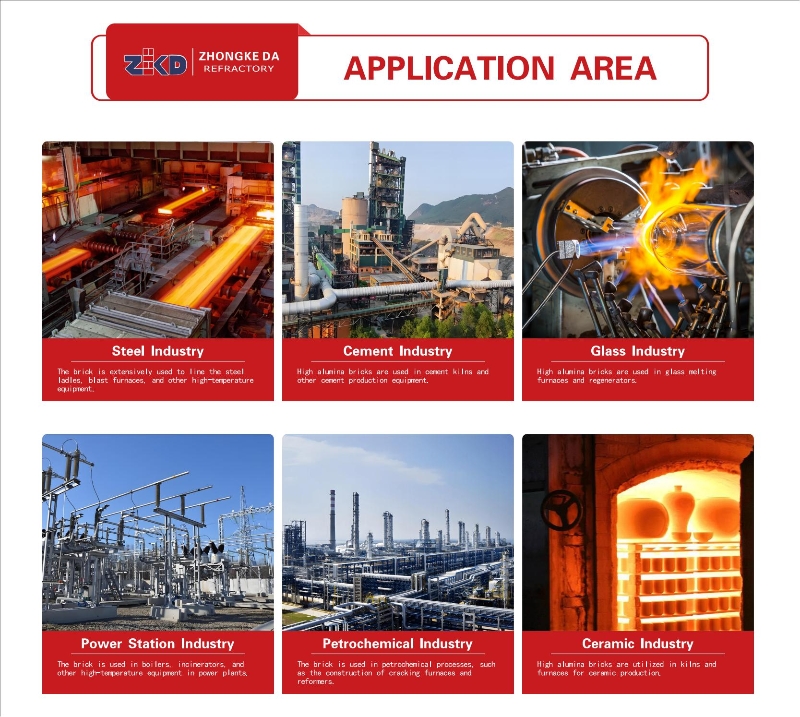

Applications of Sillimanite Bricks:

•Blast Furnaces: Checkers, stoves, upper stack linings.

•Hot Blast Stoves: Checker chambers, dome linings.

•Glass Furnaces: Regenerator chambers, superstructure areas exposed to thermal cycling.

•Ceramic Kilns: Kiln cars, setters, firing zones requiring thermal shock resistance.

•Coke Ovens: Doors, jambs, combustion chamber walls.

•Heat Treatment Furnaces: Where thermal cycling is frequent.

•Non-Ferrous Metal Furnaces: Linings requiring stability against thermal shock.

Parameters of Sillimanite Bricks:

| Item | GXS65 | GSX60 | |

| Al₂O₃,% | ≥ | 65 | 60 |

| SiO₂,% | ≤ | 32 | 37 |

| Fe₂O₃,% |

≤ |

0.5 | 1.0 |

| Bulk Density,g/cm³ |

≥ |

2.5 | 2.3 |

| Apparent Porosity,% |

≤ |

18 | 19 |

| Cold Crushing Strehgth,MPa |

≥ |

80 | 80 |

| 0.2MPa Refractoriness Underload,℃ |

≥ |

1650 | 1600 |

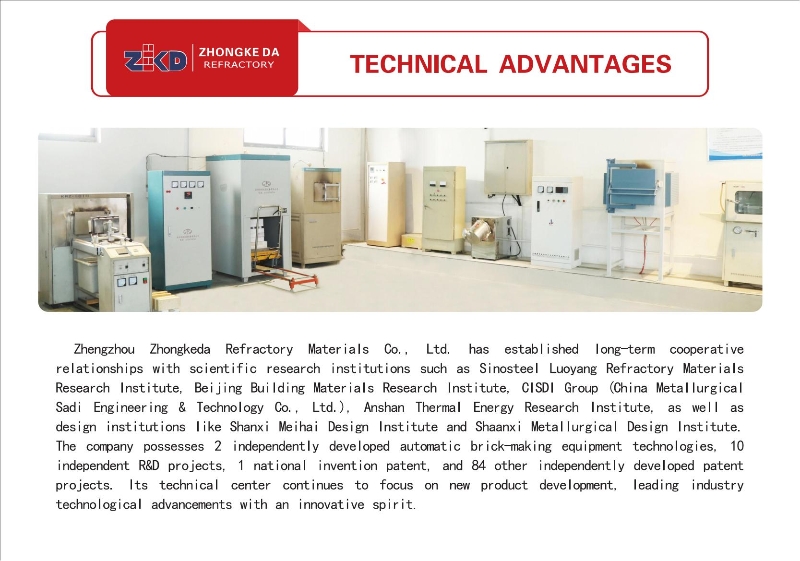

Zhengzhou Zhongkeda Refractory Materials Co., Ltd

Zhengzhou Zhongkeda Refractory Materials Co., Ltd