Magnesium Aluminum Spinel Brick

Magnesia-Alumina Spinel Bricks - High-Performance Refractory Solution for Cement & Steel Industries

Magnesia-Alumina Spinel Brick is a refractory material made from high-purity magnesia (MgO) and synthetic magnesia-alumina spinel (MgAl₂O₄) as the main raw materials. It is sintered at ultra-high temperatures above 1800°C in a tunnel kiln. Its primary mineral phase is magnesia-alumina spinel , which features a unique crystal structure and high stability.

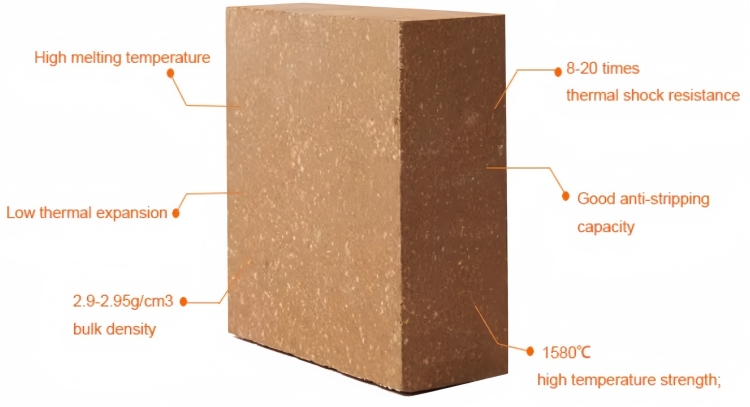

Characters of Magnesia-Alumina Spinel Bricks:

✅ Excellent resistance to thermal shock and spalling

✅ Superior corrosion resistance to basic slags and alkalis

✅ High refractoriness under load (RUL)

✅ Stable structure at high temperatures

✅ Long service life in harsh furnace conditions

Typical Applications of Magnesia-Alumina Spinel Bricks:

•🔥Transition and burning zones of cement rotary kilns

Designed for extreme conditions in cement rotary kiln transition/burning zones, resistant to temperatures exceeding 1600°C and alkali erosion.

•⚙️Steel ladles, tundish linings, RH degassing systems

Full-process steelmaking protection: Steel ladle linings withstand molten steel erosion, tundish resists slag corrosion, and RH degassing systems combat thermal shock.

•🏭Lime kilns and non-ferrous metal furnaces

Engineered for lime kiln calcination zones and non-ferrous metal (Cu/Al) smelting furnaces, balancing thermal conductivity with resistance to CO/sulfide corrosion.

•⚡Secondary refining equipment

Dedicated refractory solutions for LF/AOD furnaces, ensuring stability and longevity in low-oxygen refining environments.

Parameters of Magnesia-Alumina Spinel Brick:

FAQ:

Item

MAJ-01

MAJ-02

MAJ-03

MAJ-04

MgO,(%)≥

88

86

84

82

Al₂O₃,(%)≥

6

9

9

8

SiО₂,(%)≥

0.5

0.5

0.8

1.0

Bulk density, (g/cm³)

2.9

2.9

2.85

2.8

Open porosity,(% )≤

18

18

19

20

Compressive strength, (N/mm²)≥

60

60

50

45

Softening onset temperature, (℃), ≥

1700

1700

1680

1650

Thermal resistance, (times)≥,

10

10

10

10

Thermal conductivity, 1000℃, (W/m•K)

2.9

2.9

2.8

2.7

Q: Can you customize the brick size, shape, or chemical composition?

A: Yes, we offer complete customization services, including special shapes, dimensions, and formulations tailored to your specific furnace and process requirements.

Q: What is your Minimum Order Quantity (MOQ)?

A: Our standard MOQ is 10 tons, but we are open to smaller trial orders for first-time cooperation or new project developments.

Q: How do you package the bricks for shipment?

A: Bricks are securely packed in seaworthy wooden pallets or crates, protected with waterproof wrapping to ensure safe delivery even over long distances.

Q: How long does production and delivery usually take?

A: Production typically takes 20–35 days after order confirmation, depending on the order size and customization details.

Q: Can you provide technical installation support?

A: Absolutely. We offer installation guidance, lining design advice, and technical support throughout the project to help you achieve the best performance.

Q: Can I request a sample before placing a bulk order?

A: Yes, samples are available upon request. Shipping charges for samples are typically paid by the buyer.

Q: Do your products have quality certifications?

A: Yes. All products are manufactured under strict quality control systems and can be supplied with ISO certifications, chemical analysis reports, and third-party inspection certificates if needed.

Zhengzhou Zhongkeda Refractory Materials Co., Ltd

Zhengzhou Zhongkeda Refractory Materials Co., Ltd