High Chrome Brick

High Chrome Bricks - Exceptional Corrosion Resistance for Aggressive Industrial Environments

High chrome bricks are refractory materials with chromium oxide (Cr₂O₃) as the main component (typically ≥70%). The bonding phase may contain small amounts of aluminum oxide (Al₂O₃), magnesium oxide (MgO), or silicon carbide (SiC). These bricks exhibit exceptional corrosion resistance and high-temperature stability, making them ideal for use in extremely aggressive environments.

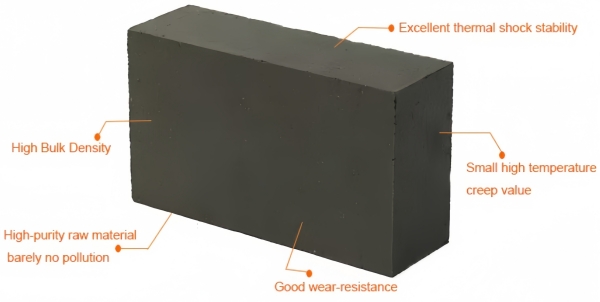

Characters of High Chrome Bricks:

•✅High Cr₂O₃ content for superior slag and alkali resistance

•✅Excellent corrosion resistance in harsh chemical environments

•✅Outstanding high-temperature mechanical strength

•✅Good thermal shock resistance and volume stability

•✅Long service life in aggressive furnace atmospheres

Main Applications of High Chrome Bricks:

•🏭Non-Ferrous Metallurgy: Copper, nickel, and zinc smelting furnaces

•🧪Chemical Industry: Sulfuric acid plant linings

•🔥Glass Industry: Glass tank regenerators, waste gas treatment

• ⚙ Waste Incineration: Rotary kilns and secondary combustion chambers

• 🏗 Cement Industry: Preheater and kiln linings exposed to chemical attack

Parameters of High Chrome Bricks:

|

Item |

GGZ-75 |

GGZ-85 |

GGZ-90 |

GGZ-95 |

|

Cr₂O₃ Content (%)≥ |

75 | 85 | 90 | 95 |

|

(Cr₂O₃+Al₂O₃+ZrO₂) Content (%)≥ |

98 | 98 | 98 | 98 |

|

SiO₂ Content (%)≤ |

0.2 |

0.2 |

0.2 |

0.2 |

|

Fe₂O₃ Content (%)≤ |

0.3 |

0.3 |

0.3 |

0.3 |

|

(K₂O+Na₂O) Content (%)≤ |

0.2 |

0.2 |

0.2 |

0.2 |

|

Apparent Porosity,(%)≤ |

18 | 18 | 16 | 16 |

|

Bulk Density,(g/cm³)≥ |

3.9 | 4.2 | 4.22 | 4.25 |

|

Cold Crushing Strength, MPa ≥ |

120 | 120 | 120 | 120 |

FAQ:

Q: What makes High Chrome Bricks different from other refractory bricks?

A: Compared to traditional refractory bricks, High Chrome Bricks offer superior resistance to chemical attack, especially from alkalis, slags, and acidic gases, making them ideal for extremely aggressive environments.

Q: What industries typically use High Chrome Bricks?

A: High Chrome Bricks are widely used in non-ferrous metal smelting (copper, nickel, zinc), glass furnaces, chemical processing plants, waste incinerators, and cement kilns exposed to corrosive atmospheres.

Q: What is the typical Cr₂O₃ content in your High Chrome Bricks?

A: Depending on the grade, the Cr₂O₃ content typically ranges from 60% to 90%, ensuring excellent chemical durability.

Q: What is the maximum service temperature for High Chrome Bricks?

A: High Chrome Bricks can operate stably at temperatures up to 1700°C or higher, depending on the specific application conditions.

Q: Are customized sizes and shapes available?

A: Yes, we offer custom manufacturing for non-standard sizes, shapes, and compositions to meet specific furnace design and operational needs.

Q: How is the thermal shock resistance of High Chrome Bricks?

A: High Chrome Bricks exhibit good thermal shock resistance, especially when exposed to moderate thermal cycling environments, maintaining structural integrity over time.

Q: Do you provide technical support for product selection and installation?

A: Absolutely. Our technical team can assist with material recommendations, lining design, and provide installation guidelines to ensure optimal performance.

Q: What is the typical delivery time for High Chrome Brick orders?

A: Standard lead time is usually 15–30 days, depending on order quantity and customization requirements.

Q: How do you ensure product quality?

A: We strictly follow ISO quality management systems and offer third-party inspection services upon request. Material certificates and detailed testing reports are provided with every shipment.

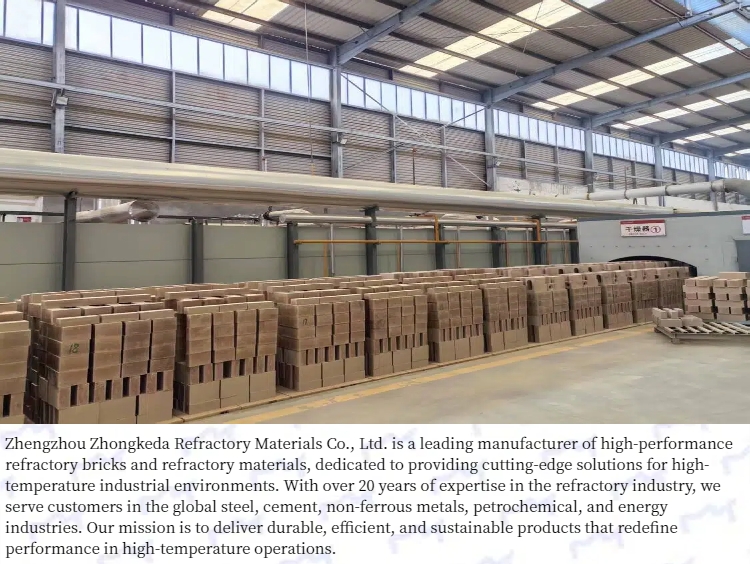

Zhengzhou Zhongkeda Refractory Materials Co., Ltd

Zhengzhou Zhongkeda Refractory Materials Co., Ltd