Acid Resistant Brick

Acid Resistant Bricks - Superior Protection Against Corrosion and Chemical Attack

🔥1300℃ Sintered |🛡️ 99% Acid Resistance | 🌍25+ Countries Served

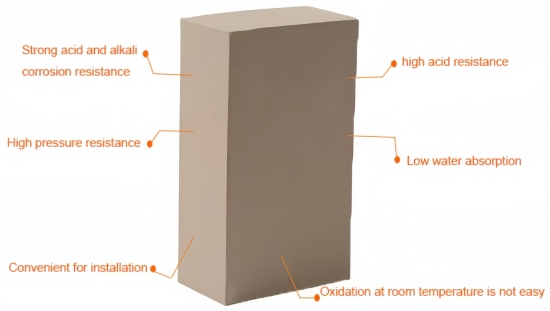

Acid Resistant Bricks are specially engineered ceramic bricks designed to withstand strong acids, alkalis, and other corrosive chemicals at both ambient and elevated temperatures. Manufactured from high-quality raw materials such as silica, feldspar, kaolin, and other chemical-resistant components, these bricks provide exceptional durability, low water absorption, and high mechanical strength — making them essential for industrial applications requiring corrosion-resistant linings.Characters of Acid Resistant Bricks:

✅ Excellent resistance to strong acids, alkalis, and chemical solvents

✅ Low water absorption and high density

✅ High mechanical strength and abrasion resistance

✅ Thermal stability and resistance to thermal shocks

✅ Long service life even under harsh chemical environments

Main Applications of Acid Resistant Bricks:

•🏭Chemical Processing Plants: Tanks, towers, reaction vessels, and drainage systems

•🏗 Acid Pickling Tanks and Floors: Steel plants, metal treatment facilities

•🏢Fertilizer Factories: Equipment linings and floors

•🌿Pharmaceutical and Food Industries: Areas exposed to aggressive cleaning agents

•🚰Sewage Treatment Plants: Corrosion-resistant linings and channels

Parameters of Acid Resistant Bricks:

| Item | Value |

| SiO₂ (%) | 60~70 |

| Al₂O₃(%) | 20~30 |

| Fe₂O₃(%) | 0.5~3.0 |

| Bulk Density, (g/cm³) | 2.3~2.4 |

|

Acid Resistance, (%) |

>99.8 |

|

Water Absorption, (%) |

≤0.5 |

|

Bending Strength, (Mpa) |

>55.8 |

|

Compressive Strength, (Mpa) |

≥120 |

FAQ:

Q1: What are Acid Resistant Bricks made of?

A1: Acid Resistant Bricks are typically made from high-silica content materials, feldspar, and carefully selected clay, fired at high temperatures to achieve exceptional chemical resistance, low porosity, and high strength.

Q2: What industries commonly use Acid Resistant Bricks?

A2: Acid Resistant Bricks are widely used in chemical plants, steel pickling lines, fertilizer production facilities, sewage treatment plants, pharmaceutical factories, and food processing industries — anywhere corrosion resistance is critical.

Q3: What types of chemicals can Acid Resistant Bricks withstand?

A3: Acid Resistant Bricks offer excellent resistance to a wide range of acids, including sulfuric acid, hydrochloric acid, nitric acid, and organic acids. They also resist most alkalis, solvents, and aggressive cleaning agents.

Q4: Can Acid Resistant Bricks withstand high temperatures?

A4: Yes, Acid Resistant Bricks maintain good structural integrity and chemical resistance at temperatures up to approximately 170°C (338°F) under continuous exposure. For higher temperatures, special grades may be available.

Q5: Do you offer custom sizes or shapes?

A5: Yes, we offer full customization services for Acid Resistant Bricks, including non-standard sizes, special shapes, and even custom color options to meet specific project requirements.

Q6: How are Acid Resistant Bricks installed?

A6: Acid Resistant Bricks are usually installed using acid-proof mortar or chemical-resistant adhesives. We can provide technical guidance, recommended installation procedures, and even supply compatible mortars if needed.

Q7: Can you provide technical support or installation advice?

A7: Absolutely. Our technical team can assist with material selection, installation design, and provide detailed instructions or on-site support as required for your project.

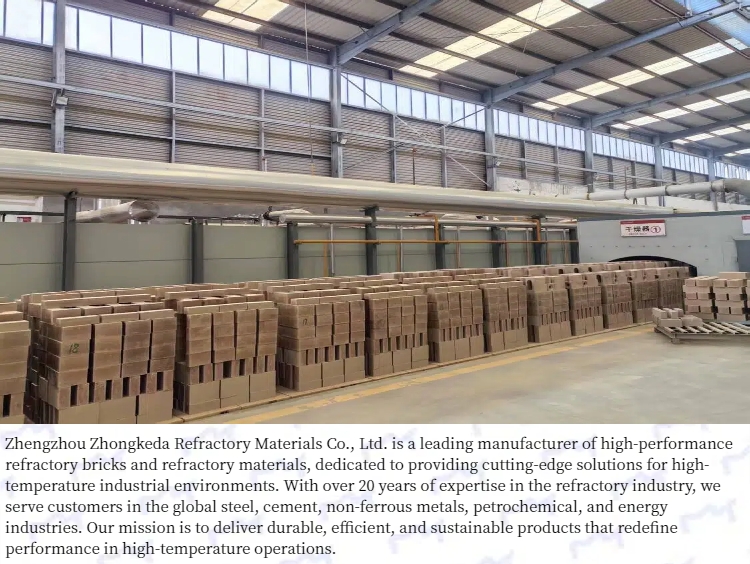

Zhengzhou Zhongkeda Refractory Materials Co., Ltd

Zhengzhou Zhongkeda Refractory Materials Co., Ltd