Magnesia Carbon Brick

Magnesia Carbon Bricks - Premium Refractory Solution for High-Temperature Steelmaking Applications

Magnesia-carbon bricks are made from high-purity magnesia, carbon materials (including graphite), and tar pitch or resin through batching, hot mixing, molding, and firing at temperatures ranging from around 300℃ to over 1000℃. These bricks effectively utilize the strong slag resistance of magnesia and the high thermal conductivity and low expansion of carbon, compensating for the poor spalling resistance of magnesia. As a result, magnesia-carbon bricks feature excellent slag resistance, good slag penetration resistance, high thermal shock stability, and superior thermal conductivity.

Characters of Magnesia Carbon Bricks:

✅ High refractoriness and strength at elevated temperatures

✅ Excellent thermal shock resistance

✅ Superior resistance to chemical corrosion and slag penetration

✅ Low thermal expansion and good oxidation resistance

✅ Prolonged service life and reduced downtime

Main Application of Magnesia Carbon Bricks:

•🏭Steel Industry: BOF, EAF, ladles, converters

•🧪Non-Ferrous Industry: Copper and nickel refining furnaces

•🔥Industrial Furnaces: High-wear lining zones

•🧱Furnace Accessories: Impact pads, slag lines, working linings

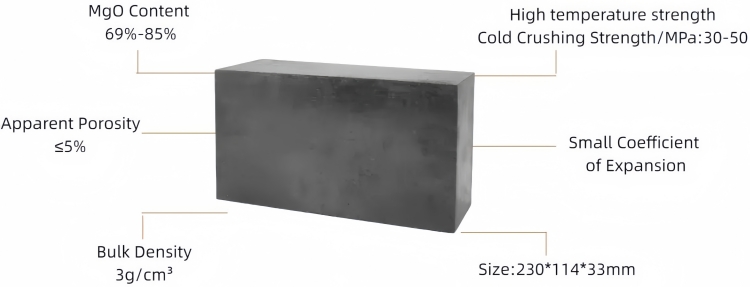

Parameters of Magnesia Carbon Bricks:

Item

Apparent Porosity(%)≥

Bulk Density(g/cm³)≥

Cold Crushing Strength(MPa)≥

MT10A

80

10

4

2.9

40

6

MT10B

78

10

5

2.85

35

5

MT10C

76

10

6

2.8

30

4

MT14A

76

14

4

2.9

40

12

MT14B

76

14

5

2.82

35

8

MT14C

74

14

6

2.77

25

5

MT18A

72

18

3

2.9

40

10

MT18B

70

18

4

2.82

35

7

MT18C

70

18

5

2.77

35

4

FAQ:

Q: What are the advantages of using Magnesia Carbon Bricks in steelmaking?

A: They provide excellent thermal shock resistance, superior corrosion resistance against slag and steel, high refractoriness, and longer service life, reducing maintenance and downtime in harsh furnace environments.

Q: In which areas of steel plants are Magnesia Carbon Bricks typically used?

A: They are commonly used in basic oxygen furnaces (BOF), electric arc furnaces (EAF), steel ladles, converters, and tundishes, especially in slag lines, impact zones, and working linings.

Q: Can the chemical composition and physical properties be customized?

A: Yes, we can tailor the MgO content, graphite percentage, and other properties according to specific working conditions and customer requirements.

Q: What is the typical service life of Magnesia Carbon Bricks?

A: Service life varies based on furnace conditions, but our high-quality MgO-C bricks typically last longer due to superior wear resistance and low oxidation loss.

Q: Do you offer technical support for brick selection and installation?

A: Absolutely. Our technical team can assist you with material selection, installation recommendations, and lining design optimization to maximize furnace performance.

Q: What is your Minimum Order Quantity (MOQ)?

A: Our standard MOQ is 10 tons, but smaller trial orders can be negotiated for new clients or specific project needs.

Q: How are Magnesia Carbon Bricks packaged for shipment?

A: Bricks are packed on fumigated wooden pallets with waterproof wrapping, ensuring safe transportation to your site.

Q: Can I request a product sample for testing before placing a bulk order?

A: Yes, samples are available upon request. Shipping costs for samples are usually borne by the buyer.

Q: Do your products meet international quality standards?

A: Yes. Our Magnesia Carbon Bricks are manufactured under strict quality control systems and can be provided with ISO certification, chemical analysis reports, and third-party inspection documents if required.

Zhengzhou Zhongkeda Refractory Materials Co., Ltd

Zhengzhou Zhongkeda Refractory Materials Co., Ltd