High Alumina Brick

High Alumina Bricks – Premium Refractory Bricks for High-Temperature Industries

High Strength | Thermal Stability | Customized Solutions

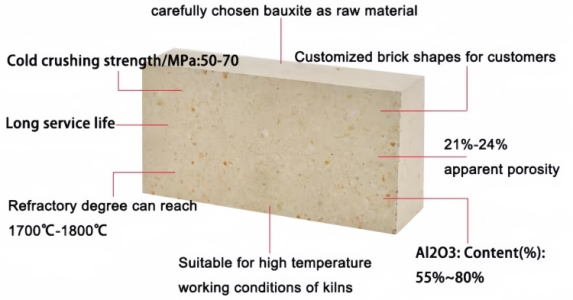

High alumina bricks are neutral refractory materials with an alumina (Al₂O₃) content of over 48%. They are made from raw materials with a high alumina content, such as clay or other materials, through molding and calcination. These bricks exhibit excellent thermal stability and can withstand temperatures above 1770°C. They also have good slag resistance.

Characters of High Alumina Brick:

•🔥High Refractoriness (≥1750°C)

•🛡️Excellent Resistance to Chemical Attack & Slag Penetration

•💪Good Thermal Shock Resistance & Dimensional Stability

•🌡️High Cold Crushing Strength (up to 90 MPa)

•📉Low Creep Rate at High Temperatures

•🏭OEM/ODM Custom Sizes & Shapes Available

Typical Applications of High Alumina Bricks:

•🔩Steel & Metallurgy: Blast furnace linings, hot blast stoves, steel ladle linings

•🏗️Cement Industry: Preheaters, rotary kiln linings, clinker cooler walls

•🔬Non-Ferrous Metallurgy: Copper smelters, aluminum refining units

•🔥Ceramic & Glass Kilns: Chamber walls, checker bricks, burner blocks

•♻️Waste Incineration Plants: High wear & corrosion zones

Parameters of High Alumina Brick:

| Item | LZ-80 | LZ-75 |

LZ-65 |

LZ-55 | LZ-48 |

|

Al₂O₃(%) |

80 | ≥75 |

≥65 |

≥55 |

≥48 |

|

Refractoriness (°C ) |

≥1790 |

≥1790 |

≥1790 |

≥1790 |

≥1790 |

|

Bulk Density (g/cm³) |

2.65 |

2.5 | 2.45 | 2.4 | 2.3 |

|

Softening Temperature Under Load (°C ) |

1530 |

≥1520 |

≥1500 |

≥1470 |

≥1420 |

|

Reheating Linear changes Rate (%)/1500℃*2h |

0.1 | 0.1 | 0.1 | 0.1 | 0.1 |

|

Reheating Linear changes Rate (%)/1450℃*2h |

-0.4 |

-0.4 |

-0.4 |

-0.4 |

-0.4 |

|

Apparent porosity (%) |

22 | ≤23 |

≤23 |

≤22 |

≤22 |

|

Cold crushing strength (Mpa) |

55 |

≥50 |

≥45 |

≥40 |

≥35 |

Q: What are high alumina bricks made of?

A:High alumina bricks are primarily made of bauxite, alumina, and other alumino-silicate raw materials. The Al₂O₃ content typically ranges from 48% to over 90%, depending on the grade.

Q:What is the maximum working temperature of high alumina bricks?

A:Standard high alumina bricks can withstand temperatures up to 1,750°C (3,182°F), depending on alumina content and application. Higher alumina grades offer superior thermal resistance.

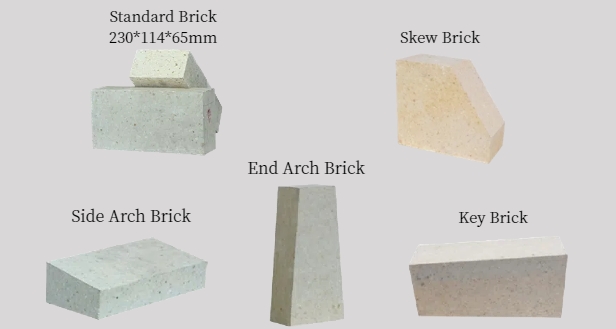

Q:Do you offer custom sizes or shapes?

A:Yes, we manufacture both standard sizes (230x114x65mm, etc.) and custom-shaped high alumina bricks based on drawings or specific requirements.

Q:Do you offer custom sizes or shapes?

A:Yes, we manufacture both standard sizes (230x114x65mm, etc.) and custom-shaped high alumina bricks based on drawings or specific requirements.

Q:What is your MOQ and delivery time for export orders?

A:•MOQ: 10 tons

•Lead Time: 7–15 working days depending on quantity and customization

•Shipping: We support FOB, CIF, EXW, and door-to-door services

Q:Can your high alumina bricks be used for direct contact with molten metal?

A:Yes, high-purity high alumina bricks are suitable for applications involving direct contact with molten steel or aluminum, especially in ladles, runners, and spouts.

Q:How are the bricks packaged for export?

A:We use:

•Standard export wooden pallets

•Shrink-wrapped and strapped

•Option for fumigated pallets or steel pallets as per customer requirements

Q:Can I order a sample before bulk purchase?

A:Absolutely. We offer free or paid samples depending on the product type and shipping region. Sample preparation typically takes 3–5 days.

Zhengzhou Zhongkeda Refractory Materials Co., Ltd

Zhengzhou Zhongkeda Refractory Materials Co., Ltd