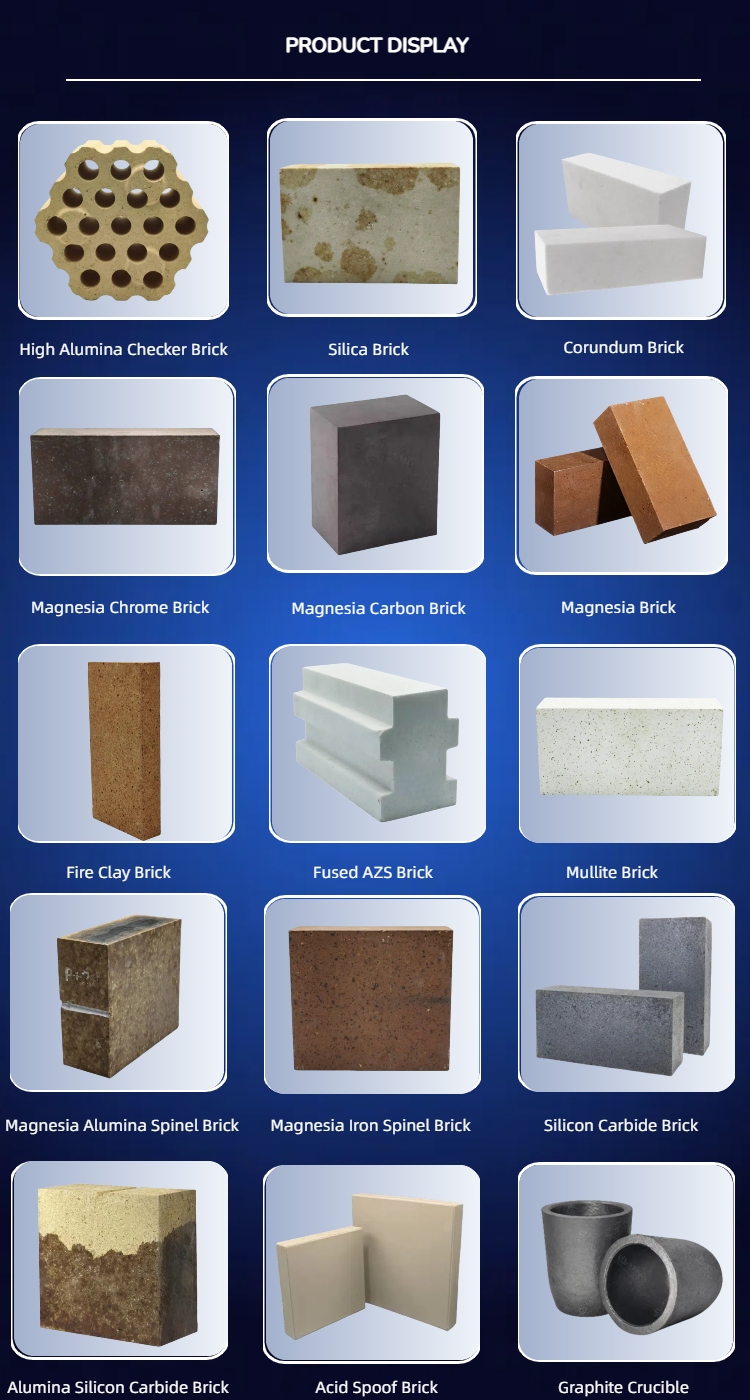

Alumina Silicon Carbide Brick

Alumina Silicon Carbide Brick | High-Performance Anti-Corrosion Refractory

Alumina Silicon Carbide Bricks are high-performance refractory products made from a combination of premium Al₂O₃ and SiC, offering an ideal balance of abrasion resistance, thermal stability, and chemical durability. These bricks are widely used in high-wear zones of furnaces, such as tapholes, slag lines, and metal-contact zones.

Manufactured using advanced pressing or casting methods and fired at high temperatures, these bricks feature low porosity and high strength, making them suitable for steelmaking, non-ferrous metallurgy, glass, and cement industries.

Key Feature of Alumina Silicon Carbon Bricks:

•Excellent resistance to slag & metal penetration

•Outstanding thermal shock resistance

•High mechanical strength at elevated temperatures

•Low porosity and high density

•Customizable shape, size, and composition

Typical Applications of Alumina Silicon Carbon Bricks:

•🧱Steel ladle working lining and slag line

•🔥Taphole area of blast furnace or BOF

•♻️Glass furnace sidewall & forehearth

•🏗Transition and burning zones of rotary kilns

•⚙️Non-ferrous metal refining furnaces

Parameters of Alumina Silicon Carbon Bricks:

|

Item |

SMA-1680T |

GM-1680 |

GM-1650 |

GM-1550 |

|

Al₂O₃(%)≥ |

68 | 65 | 65 | 60 |

|

SiO₂+SiC(%)≥ |

30 | 30 | 30 | 28 |

|

Density(g/cm³)≥ |

2.7 | 2.65 | 2.6 | 2.5 |

|

Normal temperature compressive strength(MPa)≥ |

90 | 90 | 85 | 80 |

|

Load softening temperature(T0.6℃)≥ |

1680 | 1680 | 1650 | 1550 |

|

Thermal shock (1100℃ water cooling). times |

15 | 15 | 10 | 10 |

|

Thermal conductivity (1100℃) (W.mk) ≤ |

1.7 | 2 | 2.3 | 2.3 |

|

Abrasion resistance coefficient (cc) |

8 | 7.8 | 8.2 | 8.5 |

FAQ:

Q1: What are the advantages of alumina silicon carbide bricks over traditional refractory bricks?

A1: Al₂O₃-SiC bricks offer superior thermal shock resistance, slag corrosion resistance, and mechanical strength at high temperatures compared to traditional fireclay or high-alumina bricks. They are ideal for slag lines, tapholes, and metal-contact zones in harsh environments.

Q2: What size and shape options are available?

A2: Standard sizes (230×114×65 mm) are available, and we offer custom shapes such as:

•Tap-hole blocks

•Slag-line tiles

•Wedge-shaped bricks

•Large-format cast blocks

We can also produce based on your technical drawings or lining design.

Q3: What kind of customization is supported?

A3: We support customization of:

•Chemical composition (adjust Al₂O₃ and SiC ratios)

•Shape and dimensions

•Anti-oxidation treatments or graphite addition

•Installation compatibility (tongue-and-groove, beveled edges, anchoring slots)

Q4: Do you provide technical support or refractory lining design?

A4: Yes. Our engineers provide:

•Lining design consultations

•Material selection support

•Installation guidelines

•On-site supervision (for bulk projects)

Q5: Can I request product samples for testing?

A5: Yes. We offer free small samples for qualified industrial buyers. Please provide usage details so we can recommend the best grade.

Zhengzhou Zhongkeda Refractory Materials Co., Ltd

Zhengzhou Zhongkeda Refractory Materials Co., Ltd