Magnesite Chrome Brick

Magnesia Chrome Brick – High-Performance Refractory Solution for Industrial Furnaces

Magnesia-chrome bricks are alkaline refractory materials composed mainly of magnesium oxide (MgO) and chromium oxide (Cr₂O₃), produced through high-temperature sintering or fusion processes. Their key characteristics include high refractoriness and strong slag resistance, making them widely used as linings in industrial furnaces operating in high-temperature and chemically complex environments.

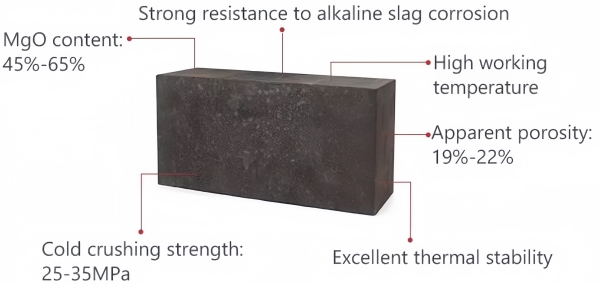

Characters of Magnesia Chrome Bricks:

•High Refractoriness: With a refractoriness of ≥1800℃, it can be used continuously at high temperatures ranging from 1600-1800℃.

•Strong Slag Resistance: Excellent resistance to both alkaline slag (e.g., steelmaking slag) and acidic slag (e.g., copper smelting slag).

•Excellent Thermal Shock Stability: Superior resistance to rapid heating and cooling compared to magnesia bricks (withstanding 10-20 cycles), with Cr₂O₃ helping to mitigate thermal stress crack propagation.

•High-Temperature Strength: Refractoriness under load (RUL) ≥1550℃, and cold crushing strength (CCS) ≥40 MPa.

Application scenarios of Magnesia-chrome bricks:

•🔥Steel industry: Ladles, EAF roofs, converters

•🛠️Non-ferrous metallurgy: Copper and nickel smelting furnaces

•🏗️Cement rotary kilns: Transition and burning zones

•🫙Glass furnaces: Regenerators and checker chambers

Different Types of Magnesia-Chrome Bricks:

•Ordinary Magnesia-Chrome Brick: Made from regular magnesia and refractory-grade chromite.

•Direct-Bonded Magnesia-Chrome Brick: Made from high-purity magnesia and chrome concentrate.

•Fused Rebonded Magnesia-Chrome Brick: Made primarily from fused magnesia-chrome sand.

•Fused Semi-Rebonded Magnesia-Chrome Brick: Made from a combination of fused magnesia-chrome sand, sintered magnesia, chromite, or pre-reacted magnesia-chrome sand.

Parameters of Magnesia-chrome bricks:

| MgO | Cr₂O₃(%) | SiO₂ | Apparent Porosity | Bulk Density | Cold Crushing Strength | 0.2MPa Refractoriness Under Load | Thermal Shock Resistance 1100°Water Cool | ||

| Item | (%)≥ | (%)≥ | (%)≤ | (%)≤ | (g/cm³)/% | (MPa)≥ | (℃) ≥ | (times) | |

| Ordinary Magnesia Chrome Bricks | MGe-8 | 65 | 8~10 | 6 | 20 | 2.95 | 35 | 1600 | 3 |

| MGe-12 | 60 | 12~14 | 4.5 | 20 | 3 | 35 | 1600 | 3 | |

| MGe-16 | 55 | 16~18 | 3.5 | 18 | 3.05 | 45 | 1700 | 4 | |

| Direct Bonded Magnesia Chrome Bricks | ZMGe-8 | 78 | 8~11 | 2 | 18 | 3.05 | 45 | 1680 | 6 |

| ZMGe-12 | 72 | 12~15 | 1.8 | 18 | 3.1 | 45 | 1700 | 5 | |

| ZMGe-16 | 62 | 16~19 | 1.8 | 18 | 3.1 | 45 | 1700 | 5 | |

| Fused Semi-recombined Magnesia Chrome Bricks | BMGe-16 | 62 | 16~18 | 1.7 | 17 | 3.15 | 50 | 1700 | 6 |

| BMGe-20 | 58 | 20~22 | 1.5 | 16 | 3.15 | 45 | 1700 | 5 | |

| BMGe-24 | 53 | 24~26 | 1.5 | 16 | 3.2 | 45 | 1700 | 5 | |

| BMGe-26 | 50 | 26~28 | 1.5 | 16 | 3.2 | 45 | 1700 | 5 | |

| Fused Recombined Magnesia Chrome Bricks | RBTRMC-16 | 65 | 16~19 | 1.5 | 16 | 3.2 | 55 | 1700 | 5 |

| RBTRMC-20 | 60 | 20~23 | 1.2 | 16 | 3.25 | 60 | 1700 | 5 | |

| RBTRMC-24 | 55 | 24~27 | 1.5 | 16 | 3.2 | 60 | 1700 | 5 | |

| RBTRMC-28 | 50 | 28~31 | 1.5 | 17 | 3.26 | 60 | 1700 | 4 |

Q: What is the difference between Magnesia Chrome Bricks and Magnesia Bricks?

A:Magnesia Chrome Bricks contain both magnesia (MgO) and chromite (Cr₂O₃), offering better corrosion and thermal shock resistance compared to pure magnesia bricks. They are particularly effective in basic slag environments and metal smelting applications.

Q: Do you offer customized sizes and compositions?

A:Yes, we provide OEM and custom solutions based on your technical requirements. This includes:

•Customized dimensions and shapes

•Specific MgO/Cr₂O₃ ratios

•Packaging with private labeling

Feel free to send us your drawing or specification for a tailored solution.

Q:How do you pack and ship Magnesia Chrome Bricks for export?

A:We pack bricks in fumigated wooden pallets or wooden boxes with waterproof wrapping and edge protection to prevent damage during transit. Our logistics team ensures on-time global shipping with full export documentation support.

Q:What is your minimum order quantity (MOQ)?

A:For export orders, our typical MOQ is 20 tons (1x20ft container). However, trial orders or sample orders can be arranged for new partners to test product quality.

Q:Are your Magnesia Chrome Bricks environmentally friendly?

A:Yes. We follow strict environmental and safety standards in raw material selection and production. Our bricks are low in impurities, and Cr⁶⁺ content is controlled, ensuring they meet global environmental compliance.

Q:Do you support long-term B2B partnerships?

A:Yes. We work with global distributors, contractors, and industrial end-users to build long-term cooperation. Exclusive pricing, regional protection, and steady supply can be negotiated for large-scale partners.

Zhengzhou Zhongkeda Refractory Materials Co., Ltd

Zhengzhou Zhongkeda Refractory Materials Co., Ltd